HM 4040 SWE

Product Description

Membrane Type: Cross Linked Fully Aromatic Polyamide Composite

Construction: Spiral Wound Element

Application: Sea Water Application

Feed Spacer: 34 mil (0.864 mm) with modified Geometry

Salt Rejection: 99.7%

| Model | Diameter Inches | Active Surface Area Ft2(m)2 | Salt Rejection % | Product Flow Rate gpd (l/h) |

| HM 4040 – SWE | 4.0 | 85 (7.89) | 99.7% | 1700 (268.13) |

Test Conditions

Feed Water Pressure: 800 psi (56.25 kg/cm2)

Feed Water Temperature: 77℉ (25℃)

Feed Water Concentration: 32000 ppm NaCl Solution

Recovery Rate: 7%

Feed Water pH: 6.5 – 7

Notes:

Minimum salt rejection is 99.6%

Permeate flow may vary +/-15%

Membrane active area variation – +/- 2

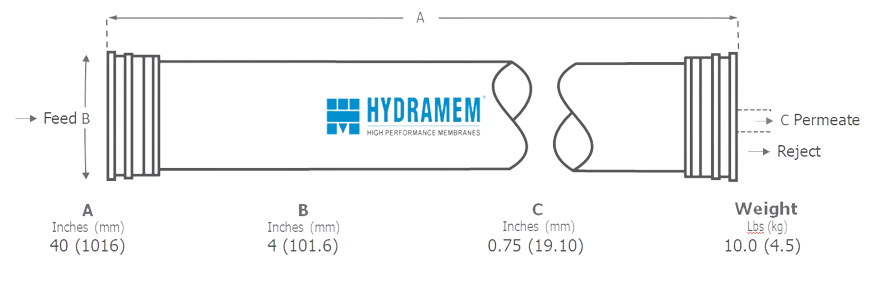

Dimensions