HM 1810 LPE 60

Product Description

Membrane Type: Cross Linked Fully Aromatic Polyamide Composite

Construction: Spiral Wound Element

Application: Drinking Water

| Model | Diameter Inches | Salt Rejection % | Product Flow Rate gpd (l/h) |

|---|---|---|---|

| HM 1810-LPE-60 | 1.8 | 95% | 60 (9.45) |

Test Conditions

Feed Water Pressure: 75 psi (5.2 kg/cm2)

Feed Water Temperature: 77oF (25oC)

Feed Water Concentration: 500 ppm softened tap water

Recovery Rate: 25%

Feed Water pH: 6.5 – 7

Notes:

Minimum salt rejection is 90%

Permeate flow may vary +/-20%

Dimensions

Operating Limits

Maximum Operating Pressure: 150 psi (10.5 kg/cm2)

Maximum Operating Temperature: 104oF (40oC)

Maximum Cleaning Temperature: 104oF (40oC)

Feed Water Chlorine Concentration: Not Detectable

Feed Water pH Range, Continuous Operation: 2 – 11

Maximum Feed Water SDI (15 Minute Test): SDI < 5

Maximum Feed Turbidity: NTU < 1

Operating Information

- Follow instructions mentioned on the caution sticker placed on product packaging.

- The customer is fully responsible for the effects of chemicals that are incompatible with the elements.

- For element loading, use only the recommended silicon lubricant. The use of petroleum based lubricant or vegetable based oils may damage the element irreversibly.

- Membranes show some resistance to short-term attack by chlorine (Hypochlorite). Continuous exposure should be avoided as it may damage the membrane.

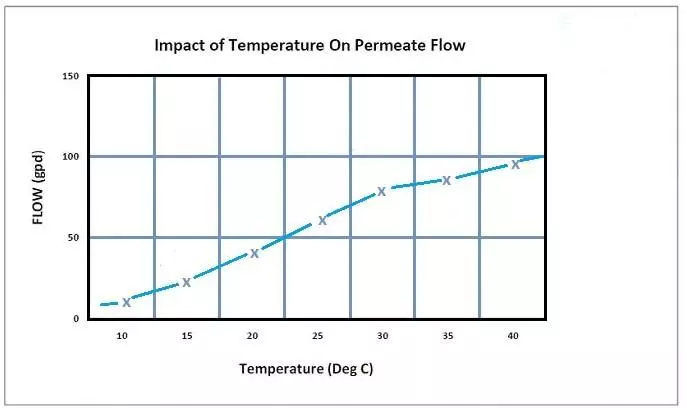

Impact of Temperature on Permeate Flow (Keeping Recovery and Pressure Constant)