HM 8040 SWE 400

Product Description

Membrane Type: Cross Linked Fully Aromatic Polyamide Composite

Construction: Spiral Wound Element

Application: Sea Water

Feed Spacer: 34 mil (0.864 mm) with modified Geometry

Boron Rejection (Typical)*: 90%

| Model | Diameter Inches | Active Surface Area Ft2(m)2 | Salt Rejection % |

Product Flow Rate gpd (l/h) |

| HM 8040-SWE-400 | 8.0 | 400 (37.16) | 99.7 | 10000 (1577) |

Test Conditions

Feed Water Pressure: 800 psi (56.25 kg/cm2)

Feed Water Temperature: 77℉ (25℃)

Feed Water Concentration: 32000 ppm NaCl solution

Recovery Rate: 10%

Feed Water pH: 7.2

Notes:

Minimum salt rejection is 99.6%

Permeate flow may vary +/-15%

Membrane active area variation – +/- 2

*When tested at standard test conditions with 5 ppm Boron in feed solutions

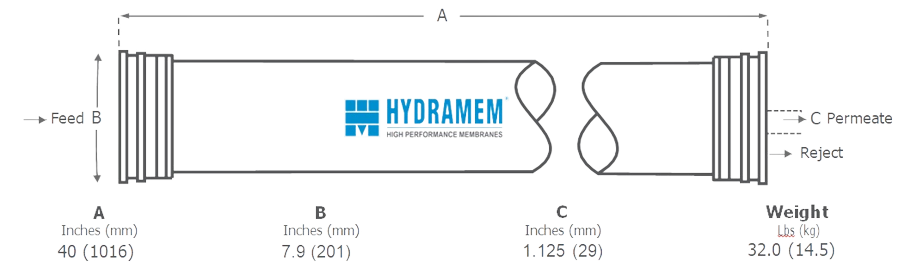

Dimensions

Operating Limits

Maximum Operating Pressure: 1200 psi (84.37 kg/cm2)

Maximum Operating Temperature: 113℉ (45℃)

Maximum Feed Flow: 75 GPM (17.0 m 3/h)

Feed Water Chlorine Concentration: <0.1 ppm

Feed Water pH Range, Continuous Operation: 2-11

Feed Water pH Range, Chemical Cleaning: 1-13

Maximum Feed Water SDI (15 Minute Test): SDI ≤ 5

Maximum Feed Turbidity:NTU ≤ 1.0

Maximum Pressure Drop for each Element: 15 psi

Maximum Pressure Drop for each Vessel: 50 psi

Minimum Ratio of Concentrate to Permeate Flow for any Element: 5:1

Operating Information

- For the recommended design range, please consult the latest HYDRAMEM technical bulletin, design guidelines, or call an application If the operating limits given in this product information bulletin are not strictly followed, the Limited Warranty will be null and void

- All elements are wet tested, treated with 1% by weight sodium Meta bisulfate preservative solution, and then vacuum packed in oxygen barrier To prevent biological growth during short term system shutdown, it is recommended that HYDRAMEM elements be immersed in a protective solution containing 500-1000 ppm of sodium Meta bi sulte dissolved in permeate. Rinse out preservative before use

- Permeate from the rst hour of operation should be discarded

- The customer is fully responsible for the effects of chemicals that are incompatible with the Their use will void Limited Warranty

- For element loading, use only the recommended silicon The use of petroleum based lubricant or vegetable based oils may damage the element irreversibly

- Membranes shows some resistance to short-term attack by chlorine (Hypochlorite).Continuous exposure may damage the membrane and should be avoided

To the best of our knowledge the information contained in this publication is accurate. Ion Exchange (India) Ltd., maintains a policy of continuous development and reserves the right to amend the information given herein without notice. Please contact our regional/branch office for current product specifications.