HM UF 60 PES High Performance Ultrafiltration Module

- High Strength Modified PES Hollow Fiber Membranes

- Low Operating Pressure & Power Consumption

- No Air Scouring required

Membrane Specifications

| Model |

|

HM UF 60 PES |

| Type |

|

Hollow Fiber Ultrafiltration |

| Material |

|

Modified Polyether Sulphone |

| Nominal Pore Size |

nm (µ) |

20 (0.02) |

| MWCO |

Dalton |

100,000 |

| Fiber Bore Diameter (Inner) |

mm |

0.9 |

| Fiber Bore Diameter (Outer) |

mm |

1.5 |

| MOC: |

|

|

| Housing |

|

UPVC |

| End Cap / Couplings |

|

GFPP |

Module Data

| Membrane Surface Area (Active) |

m 2 |

60 |

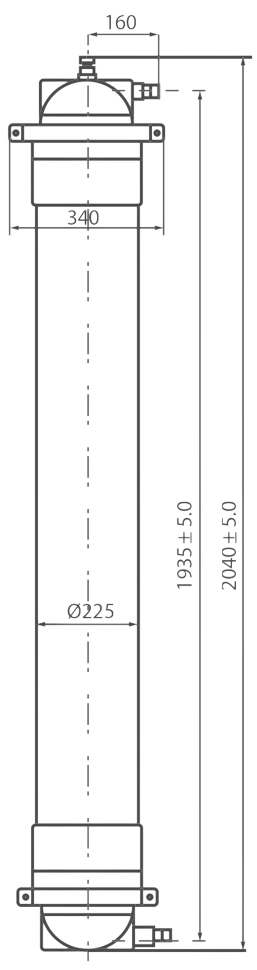

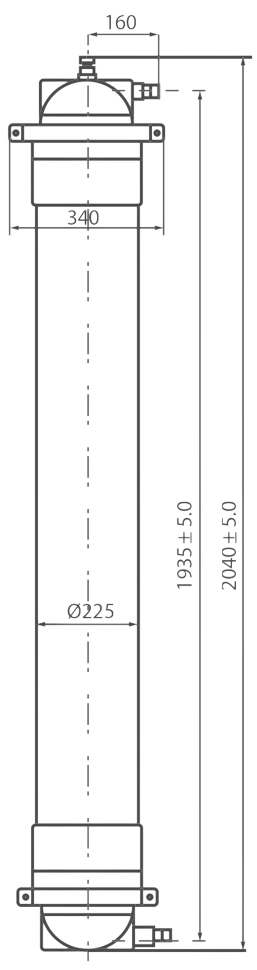

| Outer Diameter Housing |

mm |

225 |

| Total Module Length |

mm |

2040 ± 5.0 |

| Distance between feed ports |

mm |

1935 ± 5.0 |

| Distance feed – module center axis |

mm |

160 ± 2.0 |

| Feed / Permeate Port |

Inch |

2″ Victaulic End |

| Backwash In / Out |

Inch |

2″ Victaulic End |

| Empty Weight With End caps |

kgs |

50 |

Operational Data

| Mode of Operation |

|

In to Out (Dead End / Cross Flow) |

| Operating Flux Range |

gfd (lmh) |

18 – 70 (30 – 120) |

| Operating Temperature |

°C |

15 – 45 |

| Feed Pressure Operating Range |

bar |

2.0 to 2.5 |

| Burst Pressure (Housing) |

bar |

6.0 |

| Trans membrane Pressure |

bar |

1.0 – 1.4 |

| pH Range Operation |

|

4.0 – 10.0 |

| Chlorine Tolerance Instantaneous |

ppm |

250 (for short duration) |

| Chlorine Tolerance Maximum |

ppm-hrs |

200,000 |

| Max Feed TSS |

ppm |

≤ 25 |

| Max Feed Turbidity |

NTU |

≤ 25 |

| Oil & Grease |

|

Nil |

Performance Details

| Filtrate Flow Range |

gpm (m³/hr) |

8 – 32 (1.8 – 7.2) |

| Filtrate SDI |

|

≤ 3 |

| Filtrate Turbidity |

NTU |

≤ 0.5 |

| Bacteria / Virus Reduction |

log |

4 |

Process Data

| Backwash Flux |

gfd (lmh) |

100 – 141 (170 – 240) |

| Backwash Pressure |

bar |

1.5 – 2.5 |

| Backwash Frequency |

|

Once in every 30 – 60 min* |

| Backwash Duration |

sec |

30 – 60* |

| Forward Flush Duration |

sec |

15 – 45* |

| Forward Flush Flow |

m³/hr |

Feed Flow* |

| Chemical Enhanced Backwash |

|

Once in 8/16/24 hrs* |

| NaOH |

pH |

12 — 13 |

| HCL |

pH |

3 — 4 |

| Disinfection Chemicals |

|

NaOCl |

Note: *Backwash / CEB / CIP frequency & duration shall be as per the design based on the feed water source, quality & fluctuations

Important Warnings & Information:

- For the recommended design range & guidelines, please follow this technical bulletin or call an application If the operating limits given in this product information bulletin are not strictly followed, the warranty will be null and void.

- The customer is fully responsible for the effects of chemicals that are incompatible with the membrane modules.