HM UF 80 PVDF High Performance Ultrafiltration Module

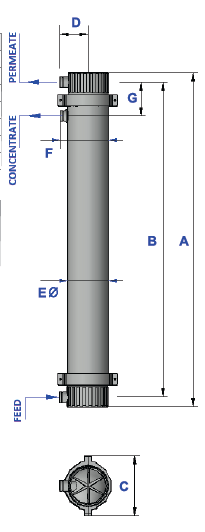

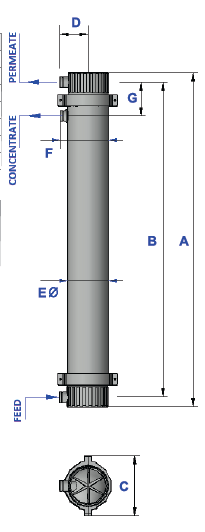

| MODEL |

Surface Area (m2) |

Dimensions (mm) |

Weight (kg) |

| A |

B |

C |

D |

E |

F |

G |

| HM UF 80 PVDF |

80 |

2038±1 |

1923±1 |

360±1 |

172±1 |

250±1 |

289±1 |

205±1 |

58 |

- PVDF based hollow fiber membranes have long lifetime due to their high mechanical strength and chemical resistance.

- The capacity of clean water production is higher due to modification of membranes

which enhances the hydrophilicity of membrane.

Membrane Specifications

| Model |

|

HM UF 80 PVDF |

| Type |

|

Hollow Fiber Ultrafiltration |

| Material |

|

Modified PVDF |

| Nominal Pore Size |

nm (µ) |

30 (0.03) |

| MWCO |

Dalton |

100,000 |

| Fiber Bore Diameter (Inner) |

mm |

0.8 |

| Fiber Bore Diameter (Outer) |

mm |

1.4 |

| Housing & End Cap (MOC) |

|

UPVC |

Module Data:

| Membrane Surface Area (Active) |

m2 |

80 |

| Outer Diameter Housing |

mm |

250 |

| Nozzels |

mm |

DN50 Victaulic End |

| Empty Weight With End Caps |

kgs |

58 |

Operational Data

| Mode of Operation |

|

Out to In (Dead End / Cross Flow) |

| Operating Flux Range |

gfd (lmh) |

26 – 105 (45 – 180) |

| Operating Temperature |

°C |

5 – 40 |

| Feed Pressure Operating Range |

bar |

2.0 – 3.0 |

| Feed Pressure Maximum @ 25°C |

bar |

5 |

| Trans membrane Pressure |

bar |

0.4 – 2 |

| pH Range Operation |

|

2.0 – 11.0 |

| Maximum NaOCl |

mg/l |

2000 |

| Particle Dimension |

µ |

< 300 |

| Total Suspended Solid (TSS) |

ppm |

50 (max 80) |

| Max Feed Turbidity |

NTU |

50 (max 250) |

| Oil & Grease |

|

Nil |

Performance Details

| Filtrate Flow Range |

gpm (m³/hr) |

15.84 – 63.38 (3.6 – 14.4) |

| Filtrate SDI |

|

≤ 2.5 |

| Filtrate Turbidity |

NTU |

≤ 0.2 |

| Bacteria Reduction |

log |

6 |

| Virus Reduction |

log |

4 |

Process Data

| Backwash Flux |

gfd (lmh) |

59 – 88 (100 – 150) |

| Backwash Pressure |

bar |

2.5 max |

| Air Scouring Flowrate |

Nm³/hr |

8 – 12 |

| Chemically Enhanced Backwash (CEB): |

|

|

| NaOH |

mg/l |

500 |

| HCL |

mg/l |

1000 |

| NaOCl |

mg/l |

1000 |

Note: Backwash / CEB / CIP frequency & duration shall be as per the design based on the feed water source, quality & fluctuations

Important Warnings & Information:

- For the recommended design range & guidelines, please follow this technical bulletin or call an application specialist. If the operating limits given in this product information bulletin are not strictly followed, the warranty will be null and void.

- The customer is fully responsible for the effects of chemicals that are incompatible with the membrane modules.